Automated Truck Loading Monitoring for Smart Logistic Management and Road Safety Control

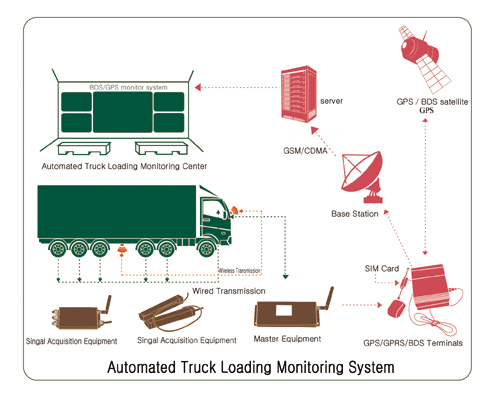

The Automated Truck Loading Monitoring for Smart Logistic Management and Road Safety Control system is comprised of the information acquisition device, the cable transmission/information transfer device, the load display instrument and the GPS/GPRS. The system does not require changing the original structure of the vehicle body, is suitable for various on-line operating vehicles, and can be rapidly installed; the GPS/GPRS and the existing logistics remote highly-matched GPS/GPRS platform can perform vehicle source overload control safety monitoring. GPS/GPRS can also serve as independent vehicle cargo load display instrument and alarm equipment.

Step 1

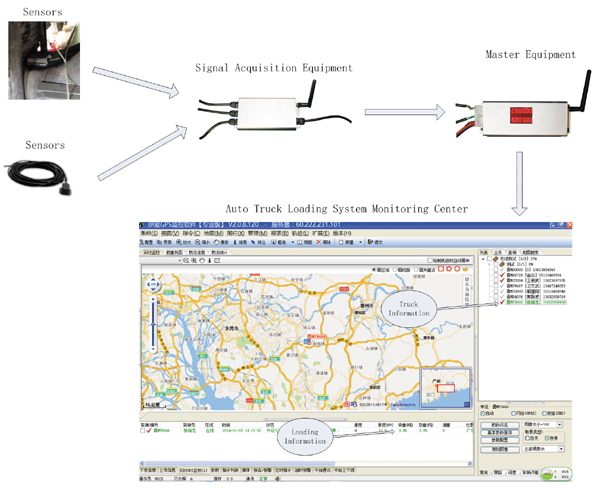

The vehicle-mounted information acquisition system can be rapidly installed in the corresponding position of the target vehicle; the single independent installation time is 1-2h; the assembly line operation can reach 0.5h/set; coefficient calibration requires a material object/weights with given weight as a reference object; and the weight of the material object/weights has different requirements according to different vehicle types.

Step 2

The acquired information is transmitted to the small display/alarm instrument (load display instrument) in the cab by signal transmission equipment through a wireless technology or wired waterproof cable. The load display instrument comprehensively processes wireless and wired signals, and displays the whole load condition of the vehicle.

Step 3

The instrument is connected with equipment such as vehicle-mounted small GPS / GPRS / Big Dipper by RS232 dedicated serial ports and transmits the load signal.

Step 4

The information is transmitted to the overload monitoring center by equipment such as GPS/GPRS/ Big Dipper, so as to achieve multi-level terminal remote monitoring.

System composition:

Overall parameter: suitable for front installation and additional installation of various operating vehicles with 3-6 axles and 4~100t load.

The system can clear truck weight and perform zero clearing; the static accuracy of the measured cargo weight is 3%; the dynamic accuracy is superior to 5% (accuracy Grade 10 in GB/T-21296-2007 Automatic Instruments for Weighing Road Vehicles in Motion); and the accuracy is related to the structure of the installed vehicle and the vehicle condition during installation.

System working voltage 9V-40V and consumption <350mA.

Working environment: The sensor can normally work at -40℃~80℃ and 5%~80% RH, and is protected by above IP65.

Load display instrument:

Singlechip microprocessor, double-row LED display, 6 significant digits, RS232serial port data input, and seamlessly butted with equipment such as GPS/GPRS/BigDipper.

The load display vehicle model is entered through the serial port, all relevantparameters are calculated and locked by password; and unauthorized people cannotset.

The instrument has functions of net weight, weight display, automatic zerotracking, creepage compensation and so on.

The number of standard channel is 6; the standard channels are compatible withdifferent sensor signals; and the I-shaped window product dimension is W*L*H-120*135*70 mm.

Signal acquisition device

Sensor type: Potentiometer, capacitor or strain type, internal resistance

120Ω~10KΩ, service temperature -40℃~100℃, and proper accuracy (0.05~0.1%) FS.

Data transmission type: High (5v), low (10mv), single-end and double-enddifferential analog or frequency output, or 4~20mA, and frequency 1-10 KHz square wave.

GPS/GPRS/Big Dipper

The typical product has the following functions:

Positioning function: Track and position multiple vehicles respectively togetherwith the monitoring terminal, and upload the longitude and latitude of the currentroute position of the terminal vehicle.

Weight display function: The terminal center display screen can display the plate

number/owner name/mobile phone number and electronic map, and can display thevehicle load weight in real time.

System features

Stable and valid data

Unique software and hardware techniques are provided, stable and valid dynamic (0~120km/h) data can be achieved, and influences of climbing, deviation, turning, vehicle head deflection and so on during driving do not exist.

Longer life

After one calibration of the sensor, the coefficient stabilization mileage is 150,000-200,000km; annual calibration can be performed. The service life is more than 3-5 years.

Excellent reliability

System loading examination exceeds one year. 200,000km has been run under various rain, snow, thunder and thermal climate conditions in the south. Multiple examination vehicles are still in normal operation and examination.

High cost performance

The like product of accuracy Grade 10 in GB/T 21296-2007 Automatic Instruments for Weighing Road Vehicles in Motion is reached by comparison, but the price is only its 1/10~1/20.